Tag: London

Case study report: London Borough of Haringey

Case study report: Old Oak and Park Royal (OPDC)

Foundries of the Future: A Guide For 21st Century Cities of Making.

Profiles: Public Practice, London

Profiles: Poplar Works, London

Profiles: East End Trades Guild, Guardians of the Arches and the London Working Rent, London

Profiles: Mark Brearley – Kaymet – London

Build it in Britain and why manufacturing matters for communities

Cities of Making: Insights From Brussels, London and Rotterdam

London’s manufacturing: a brief history

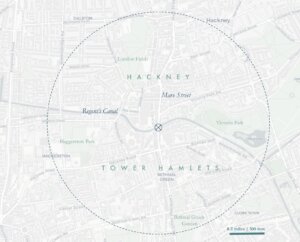

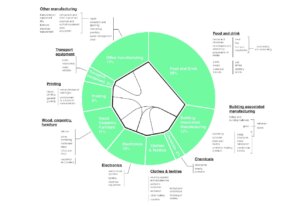

Mapping London’s makers

London: making space for manufacturing in the city

The Cities Report

Think Manufacturing in London Is No More? Think Again.

London’s celebrations of design should be celebrations of manufacturing too