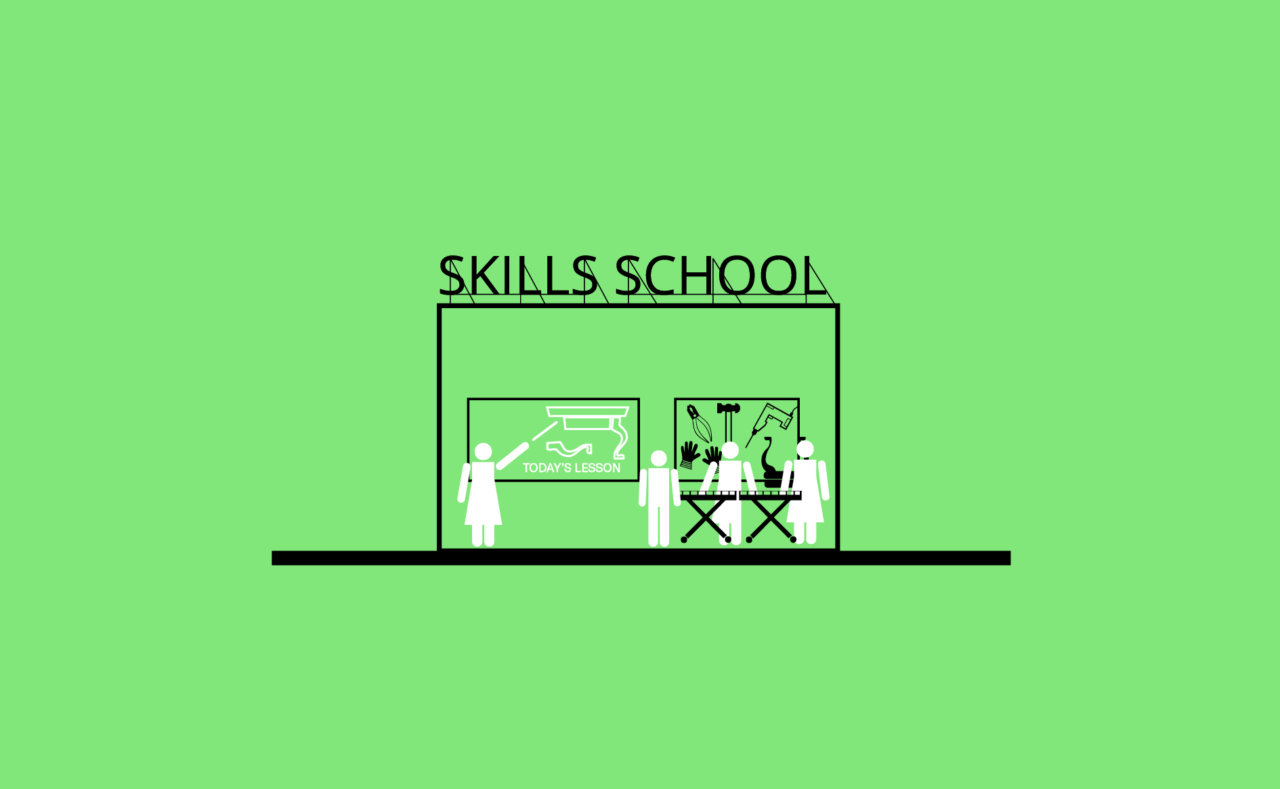

P.7 Spaces for Development and Education

Training centres are necessary to facilitate education, share knowledge and develop relevant skills.

[Context] Training, whether for basic education or development of skills and knowledge, is an essential part of manufacturing to improve the capacity, efficiency and quality of production. Various types of training exist, ranging from simple certificates (such as first aid, health and safety or equipment licences), to trades (involving apprenticeships and technical education in training colleges) and to tertiary level degrees requiring extensive theoretical knowledge (typically provided by universities or a professional skills institutes). Businesses generally provide some level of introductory training for all new staff to adapt to the company’s technology and production processes. In some cases, businesses have such particular work that new employees will be expected to have just general skills as training occurs largely on the job. More recently, with rapid changes to technology and production processes, short development courses have become more common to encourage incremental learning. Irrespective, spaces are required for training, spaces which allow people to easily gain skills and knowledge to adapt skills for an existing job or prepare for a new one. These spaces could come in a range of formats, from traditional trades colleges to universities and simple community spaces.

[Problem] Manufacturers complain of the difficulty to find suitably skilled workers. The decline of manufacturing jobs in many cities has also lead to serious reductions in both public support for and financing of training facilities and programs. In many cases, instead of modernising and adapting training to trends in manufacturing, training budgets have simply been cut, reducing the availability of skilled workers. Skills and training issues are different depending on the size of the company. Small and middle-sized businesses have smaller resources to create partnerships with training centres or to find rare skills on the labour market. Conversely, larger companies are increasingly providing in-house training, making it hard to replicate for complementary or competing businesses. Furthermore, with rapid change in technology, employees need regular but shorter courses and training modules to remain relevant to industry standards and for businesses to remain competitive. One of the fundamental questions remains: what role should public actors play in the development and education of staff?

[Forces] Training often relates to market demands. Many cities have changed their technical training institutions to focus more on services oriented work rather than technical and mechanical skills as this is where job growth is foreseen. Likewise, many universities and tertiary education institutions are decreasing budgets for mechanical training while shifting focus on ICT and software development as it is considered more profitable in terms of grants and training costs. Unless incentives are given for training and business development, the net result will be a loss of the ‘industrial commons’, the knowledge and technical skills that is shared across a manufacturing sector. This can be contrary to political ambitions for the likes of developing the circular economy or building technology clusters.

[Solutions] Provide spaces for development and education to ensure that staff are suitably trained, workers have opportunities to expand knowledge and employees are capable of delivering high quality goods. To prepare for the R.4 Availability of Diverse Jobs, there are three predominant training streams directly focused on manufacturing. Firstly low-skilled and repetitive jobs may need to adhere to certain standards including safety, hygiene, communications and possibly first aid. Such training could occur on-site or through an accredited training centre, especially within neighbourhoods N.3 Mixing Complementary Making & Related Services. Secondly, skilled workers, those with extensive technical training such as electricians or bakers, require classic institutional education to accredit basic knowledge, with a suitable (2-4 year) apprenticeship. To avoid using outdated machinery, equipment for education could be co-sponsored by industry groups or by locating education in P.2 Shared Technology and Making Spaces to ensure that young talent is relevant for the market. Finally, pluri-disciplinary workers, those with both technical and tertiary education, can build skills through university technical labs or maker-spaces. Examples of advanced manufacturing centres exist that combine technical training (vocational training) and theoretical knowledge (universities) within neighbourhoods N.4 Clustering Similar Making. Such spaces allow thinkers, makers and entrepreneurs to rub shoulders. Neighbourhood training spaces can be combined with a P.8 Community Hub in Making Locations while a R.3 Curator could help link available training with small and medium sized businesses. In addition, communication campaigns are needed to raise the profile of skills training programmes and centres that feed the manufacturing workforces, R.1 Making Making Visible is essential to draw interest in education.

[Contribution] Add contributions here.