B.4 Facilitating Horizontal Organisation

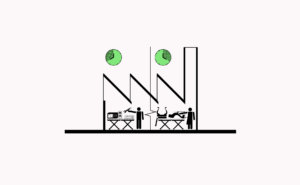

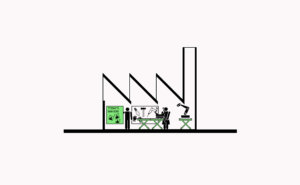

Horizontal organisation of manufacturing spaces, including smooth floors, overhead gantries and wide spacing between columns enables easy reconfiguration and safer working conditions.

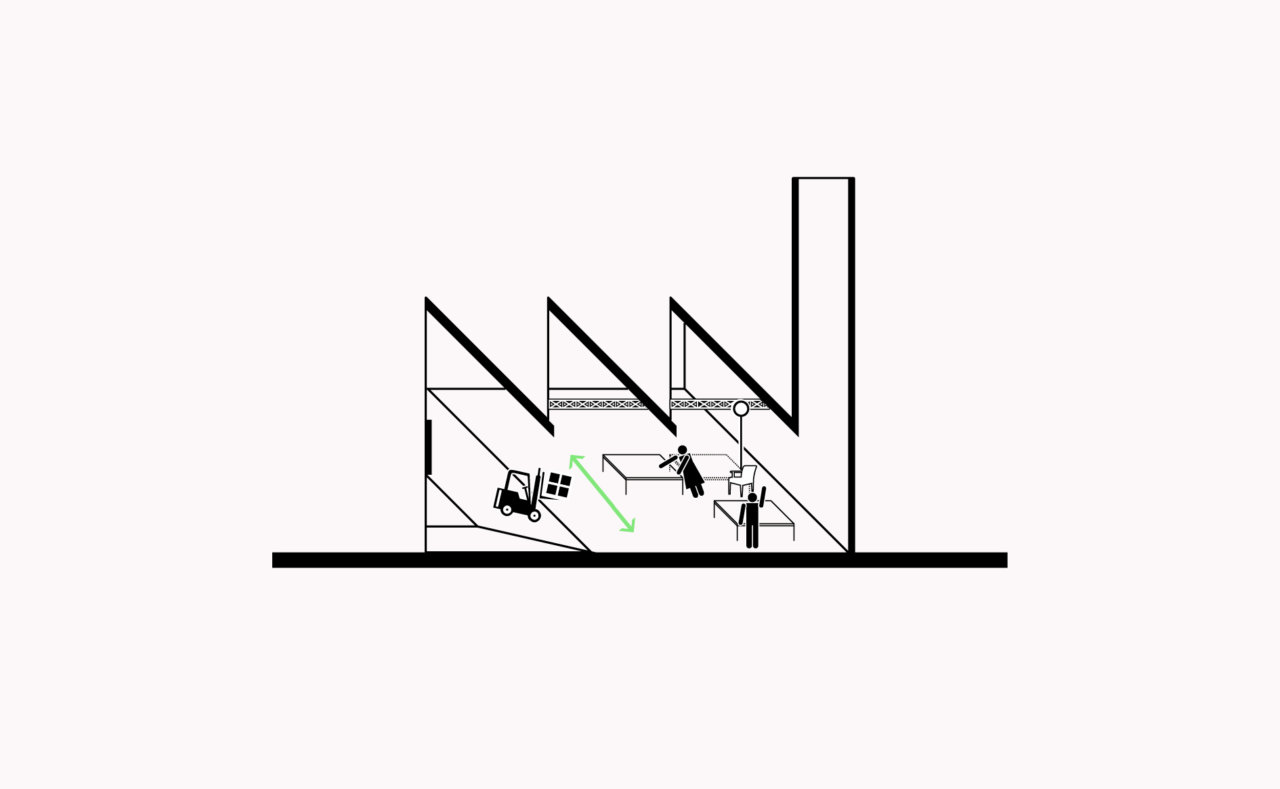

[Context] An efficient and safe manufacturing process requires the capacity for a seamless flow of people, machines and goods in and between production spaces. Generally the workflow is most efficient along a horizontal surface area, without the interruption of steps, steep ramps, columns and ceilings. This allows for the most effective configuration of large equipment and room for adaptations of the production line. Space should be provided for the free movement of forklifts, pallet carts and other transportation devices. When the production process occurs on various levels, the heaviest and most intensive activities are located on the ground floor while gravity is used where possible.

[Problem] Adapting and reusing purpose built manufacturing spaces can be problematic, particularly without contiguous floorspace, low ceilings (challenging for stacking), narrow column spacings (problematic for turning vehicles and for efficient storage) and weak structures (for storage, using forklifts and heavy machines). For new build projects, future-proofing the design of space to allow for changes in production processes and to allow new equipment to be easily moved in or out of the space.

[Forces] Due to limited space and the cost of development, it is common that manufacturing occurs in repurposed buildings and production processes are adapt to the capacity of the available space rather than the space being adapted to the potential of the production process. This can result in lower efficiencies or businesses being incapable of adapting to new technology. Where buildings are not fit for function, it may be cheaper for manufacturers to abandon the site than to redevelop it. This can be as problematic for the business as for public authorities that need to deal with vacant or poorly maintained buildings. To minimise unnecessary disturbances of the neighbourhood and avoid needless waste of resources, buildings should be adapted or reused to their best potential. This may not suit developers, who see lost potential. Where businesses do want to adapt buildings, public authorities should be flexible in allowing renovations and help fast track permit approval times to ensure that businesses are not held up by unnecessary bureaucracy. This can shortcut public policy (refer to C.2 Negotiated Qualities and Environmental Criteria). New projects should be forward thinking and ensure there is as much flexibility available in the space to allow for modifications and adaptations, which may go against developer’s ambitions. For new industrial intensification and co-location sites, policies are pushing industrial areas to grow vertically, however this means that concessions are needed to by developers to ensure buildings are fit for purpose (investment in engineering solutions to manage weight) while allowing for flexibility (minimising where possible the number of columns or walls). Many building developers responsible for industrial/housing co-location projects were formerly residential developers and simply are not aware of the loading requirements and logistics standards required by manufacturers as constructed projects can be nearly impossible to retrofit. Poorly designed buildings can render spaces unusable to businesses that have large equipment or that could be restricted by the existence of columns. Columns also allow for vibrations and noise to travel vertically, which can create further stress for mixed use buildings. Furthermore, the higher the building, the closer the columns are likely to be, with many businesses wanting wide column spans (such as no closer than 8 meters). This depends on the competency and capacity of the public authority to understand the capacity of buildings to offer flexible and adaptable spaces for manufacturing

[Solutions] Provide horizontal spaces that are as flat as possible with a limited number of columns or partitions to facilitate movement of goods and production processes. When designing or refurbishing spaces for manufacturing, preference should be given for smooth flooring, soft ramps instead of steps (max 12%), B.9 Large Openings and goods docks for B.6 Easy Loading and Unloading, wide roof spans for the sake of flexibility, workstations on casters and overhead gantries. B.7 Access to Technical Networks and Services should include solutions to avoid cables laying on the ground to avoid trip hazards. Ramps and a gentle slope are required to overcome existing differences in grade. Paint columns with colours and patterns to make them more visible, particularly for older buildings. Such spaces should facilitate R.8 Moving Things Efficiently, while ensuring R.5 Fair Work Conditions. R.10 Place-based Financial Levers can support renovations and make spaces safer and adaptable. Increasingly, B.8 Space for Storage can involve using robots or computer programmed horizontal and vertical storage to get the most out of space and move goods efficiently. For co-location or industrial intensification projects, developers must build to minimum floor loadings and column spacings, to ensure buildings are flexible and adaptable. These solutions should be taken into account for each floor when B.5 Enabling Vertical Making.

[Contribution] Add contributions here.