B.7 Access to Technical Networks & Services

Well-distributed and adequate capacity of technical networks (electricity, water, ventilation, communications and distribution channels) allows for flexible, responsive and distributed manufacturing.

[Context] Manufacturing depends on resources to ensure that production can function to full capacity. Businesses require guaranteed access to high quality and secure supplies of materials, energy and information / knowledge for production to be competitive. In the past, the location of manufacturing was heavily dependent on local resources. Traditional manufacturing areas were found next to rivers, mines or forests for suitable transport, energy and source of resources upon which the manufacturing depended. Through investment in infrastructure, resources and manufactured goods are now transported through technical networks such as power lines, pipelines and transport systems. This can allow manufacturing to occur at the location which is most affordable or profitable to the business. Technical networks can also create positive interdependencies, which lead to industrial ecology. Waste heat from one business could serve as the fuel for another, if suitable networks are provided.

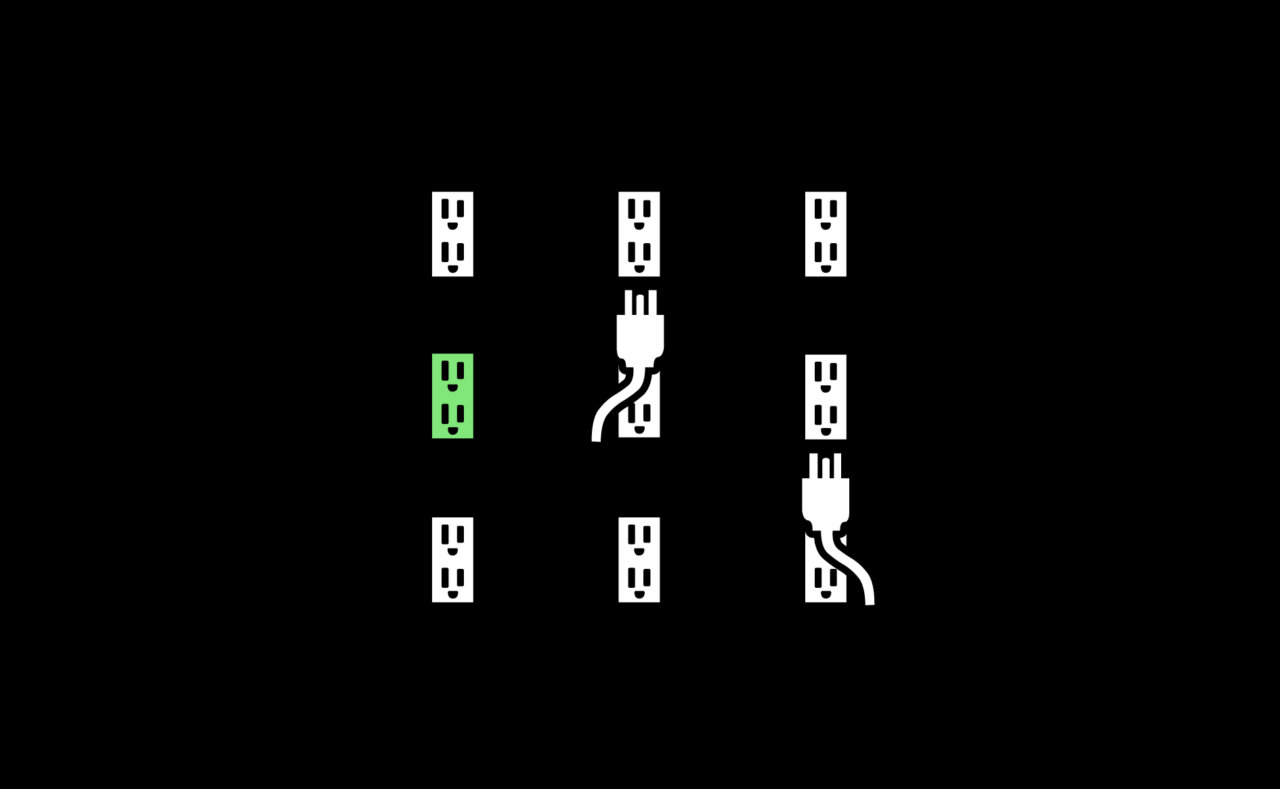

[Problem] Available technical networks can effect the type of manufacturing that is viable. Established industrial neighbourhoods may have low water pressure, electrical capacity or communications lines due to aged installations. Non-conventional sites, such as old office blocks or parking stations, which could be suitable for manufacturing, may lack the necessary electrical networks or sewage capacity. Therefore technical networks may create a serious limit for production capacity and the viability of a business. Dependence on technical networks to provide resources from across the globe is not always desirable as this can lead to absurd impacts on the source of the resource. Dependencies on unreliable local technical networks can also create resiliency challenges which is particularly the case for industrial ecology (where one business is dependent on the resource supply of another business).

[Forces] While old networks may need upgrading, it can depend on the service provider to determine if there is value in investing in upgrading or installing the network. Upfront financial costs may prevent updating and improving technical networks. This can be a limiting factor for new technology or N.2 Re-use of Materials & Energy Flows. Therefore older neighbourhoods with established manufacturers, may not gain needed network upgrades due to piecemeal adaptations and unwillingness of service providers to finance such projects. Poorly maintained technical networks can make it hard to attract new and innovative businesses that could help enrich a larger neighbourhood. Without upgrades, established industrial neighbourhoods can fail to grow or lack capacity to innovate.

[Solutions] Ensure that technical networks, at both the neighbourhood and building scale, are suitable or do not limit a business’ potential. Competitivity can be dependent on available volumes of energy, water and other resources which are supplied through networks. At a neighbourhood scale, supply can be subject to the capacity of shared infrastructure and the price of distributing resources. This will depend on local conditions (access to resources) and/or public investment in infrastructure. If there is a need for improved technical networks at a neighbourhood scale, businesses will need to build a case for public or private investment. A neighbourhood R.3 Curator could be engaged to learn about the infrastructure needs of local businesses to communicate with network providers. Doing so will provide opportunities for R.6 Sustainable Product Cycles, N.2 Re-use of Material & Energy Flows, support R.7 Multi-scalar Circular Infrastructure and contribute to rich manufacturing environments through N.3 Mixing Complementary Making & Related Services. At a building scale, technical networks can limit production and can be costly to update. Buildings subject to P.4 Meanwhile Spaces & Transitional Uses will require an evaluation of the capacities of the technical networks (particularly for fire safety) to avoid unnecessary costs or stalling short-term activities. In general it is important that technical networks are designed for flexibility and redundancy to accommodate new technologies, new forms of energy (such as renewables), energy efficiency options, water saving, heat cascading technologies as well as optimised collective use of heat and steam (such as a CHP) and R.7 Multi-scalar Circular Infrastructure. In an age of distributed manufacturing and greater levels of automation, access to fast and reliable communication networks is equally fundamental. Serious changes may require C.1 Microzoning and R.10 Place-based Financial Levers.

[Contribution] Add contributions here.