R.8 Moving Things Efficiently

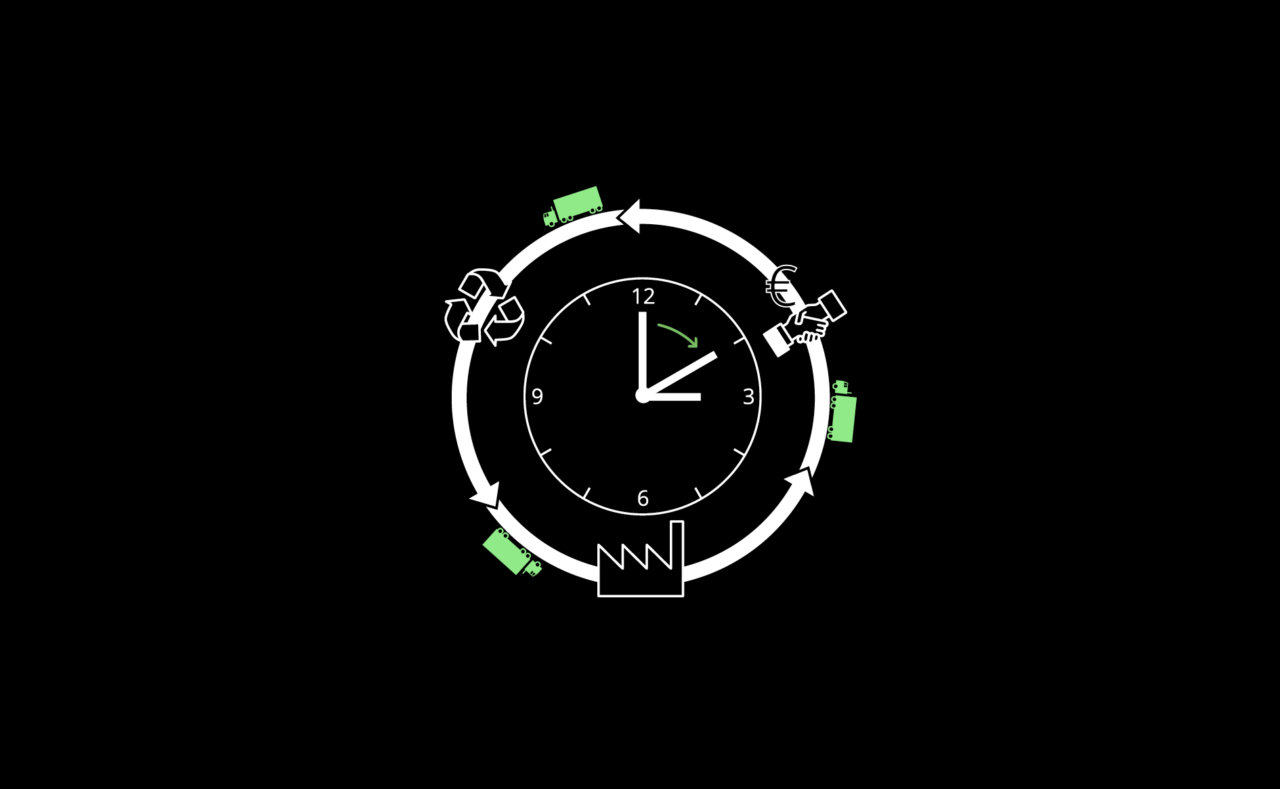

Time-distance efficiency in logistics contributes to sustainable and competitive manufacturing.

[Context] Logistics is a critical part of manufacturing. Manufacturers must ensure that their logistics systems optimise transport costs, shipping do not result in damaged goods, while delivery times are as efficient as possible (particularly) for local customers. Increasingly manufacturers are subcontracting logistics, which reduces the cost of equipment (like trucks), personnel and storage space. Furthermore, cities are increasingly taking interest in new urban logistics systems for low emissions zones, last minute delivery and smaller electric technology such as vans and bicycles. Logistics depends heavily on the business type, the goods being produced and the business’ client base. For city oriented businesses providing foundational forms of manufacturing (such as bread), deliveries are likely to remain embedded within the business but will be subject to congestion issues and urban emissions standards. For businesses with a focus on the local market but with competition from e-commerce and economies of scale from larger foreign manufacturers (such as printing), speed of production may be the strongest drawcard. These businesses will likely deliver (if bulky or delicate) or use a local courier service. Finally, businesses with a sizable export production will likely depend on fast and affordable logistics. These businesses will likely have a business model built around economies of scale or niche production which makes it attractive for such businesses to be located near a logistics centre or transport node (like a highway).

[Problem] The biggest challenge is to foresee the future of logistics. Current energy and international production chains have rendered transport cheap. But logistics is a large vulnerability for manufacturers, particularly for export oriented businesses. Global supply chains can expose businesses to global issues ranging from cost of carbon emissions to war and disease.

[Forces] Manufacturing has a strong dependence on both suppliers and clients, often who are not located in the same place. While many businesses like to cluster around C7. Links to Transport Infrastructure, large logistics companies are now often located on the edge of cities where both (commercial) clients and employees are not located. Likewise, while alternative urban logistics solutions or concepts for a N.6 Centralised Logistics Zone are being developed, not all are suited for simply delivering materials. Some businesses depend heavily on suppliers and their knowledge of materials or for using suppliers to stock material (construction related activities for example) and will therefore locate close to them. Many of these issues are encouraging businesses to move out of cities, where travel distance can be compensated by a lack of congestion. Finally, blanket policy may be placed on cities in terms of emissions or mobility levels which could directly affect manufacturers, requiring them to use energy efficient vehicles.

[Solution] Develop a city wide approach for logistics to help makers focus on making. Moving things efficiently requires a combination of well thought out storage, low impact transport and timely distribution. Manufacturers should consider if to be located close to clients and staff (C.6 Strategic Access to Multimodal Mobility) or closer to supplies and suppliers (C.7 Links to Transport Infrastructure). A N.6 Centralised Logistics Zone could allow collective storage and distribution, using vehicles that are more suited to urban conditions than large trucks while allowing night time deliveries to help evade congestion. Cities are beginning to explore alternative mobility options that are less exposed to congestion, such as the use of barges on canals and cargo-bikes. Manufacturers with a B.3 Public Face or a focus on retail should consider N.10 Making Along High Streets or N.11 Back of the High Street in order to be closer to clients. Planning instruments could facilitate better logistics by providing the right combination of infrastructure (such as collective storage, combined logistic systems) and R.10 Place-based Financial Levers. Businesses also need ways to adapt to policies oriented towards reducing congestion or improving air quality, which could include exceptions for logistics or subsidies to acquire low impact transport modes. Logistics hubs could be developed in the course of C.1 Microzoning and even acquired by public actors (C.3 Balance Between Public & Private Land).

[Contribution] Add contributions here.