C.8 Accessible Material Recovery Facilities

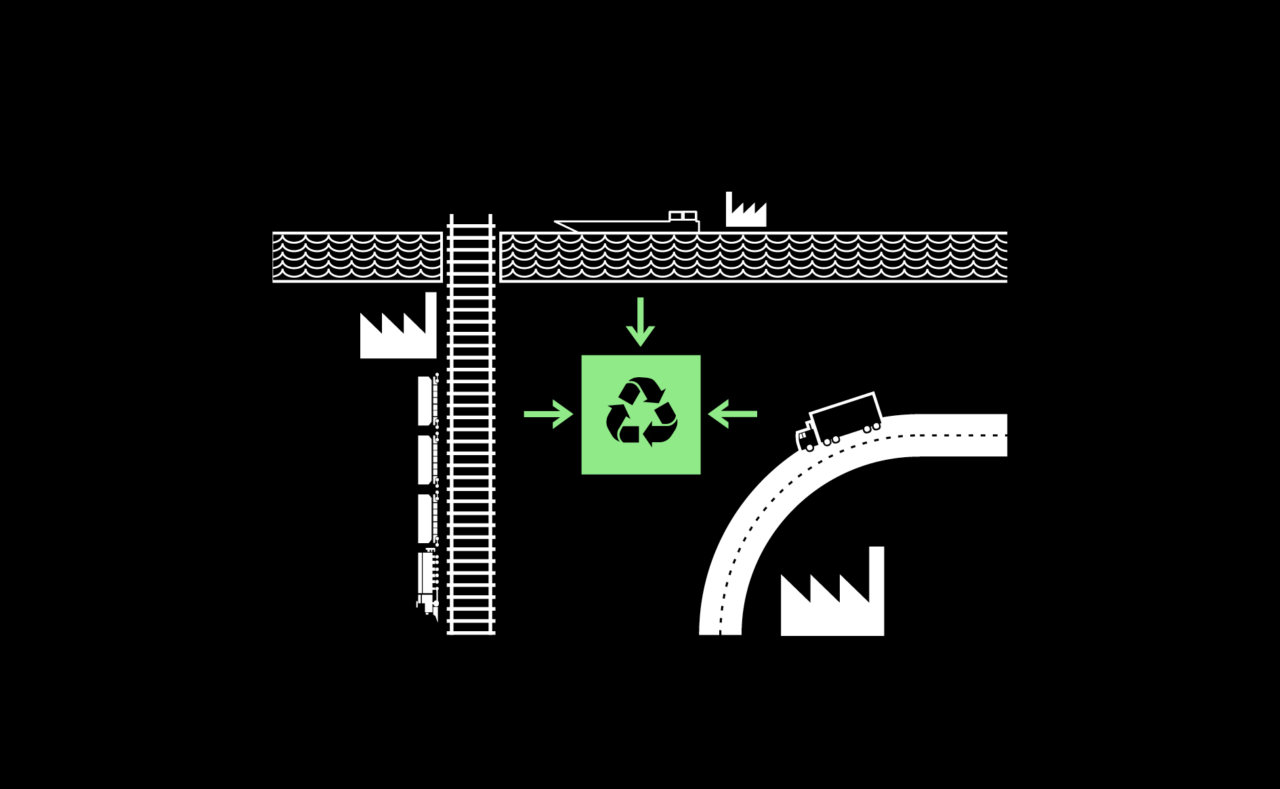

Waste processing and recycling facilities must be locally accessible through efficient logistics networks.

[Context] Local recovery facilities are a key step in capturing waste and developing business opportunities through re-using resources. Transportation of waste over long distances is generally discouraged, both legally and economically, with the exception of very specific streams of by-products with high value per volume which after transformation fall under end-of-waste status, becoming a product (such as metals). Local segregated waste collection points can help to consolidate waste streams if they’re connected to a network of recovery and processing plants that can transform waste back into a resource (or recover its energy). The value of waste materials is highly dependent on the level of purity, capacity to process materials, secondary markets and volume available. Furthermore, availability of recovery facilities depends on the type of material, the available technology (some recovery facilities are currently not commercially available for various resources), the commercial profit margins of processing waste locally, the material recovery rate and any subsidies available to help convert waste into local resources.

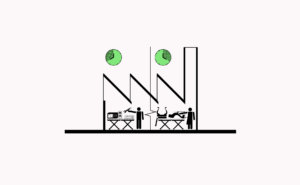

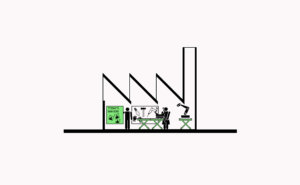

[Problem] In cities, spaces for waste processing and recovery tends to be limited and generally co-located with manufacturing activity but synergies do not tend to be developed between manufacturers and waste management for different reasons. Firstly, there may be a mismatch between required recovery processes and types of waste. Secondly, transport to waste recovery facilities needs to be undertaken by authorised waste transport vehicles. In practice, manufacturing companies often arrange collection and treatment with private waste contractors that have their own waste networks to treat their waste and dispose of residuals. Different types of waste streams may require different conditions of accessibility to recovery facilities which can make it difficult to access material flows. Specific types of waste, low value and high volume, like construction and demolition waste, cannot be transported over long distances due to the high costs associated with transport and embedded carbon emissions. For low value bulk waste, a 50km distance for recovery facilities may be required. Electronic waste P.6 Re-use and Repair Centres, in many cases associated with the social economy sector, can undertake activities separating/dismantling products to enhance recovery options, however this generally requires public support of some kind to deal with the low (or no) profit margins.

[Forces] Material recovery is highly dependent on availability, market cost and transformation capacity. For example, soft-wood is readily available but unless clean and uncut, this waste stream is largely incinerated close to the point of disposal. Steel is easily recovered and generally sold for recycling, and scrap is collected in scrap yards around the city but its’ final recovery may occur in regional or national facilities. For R.6 Sustainable Product Cycles to be desirable, the infrastructure, logistics, storage, processing capacity needs to be well understood. Initial sorting and dismantling can happen at the city scale but more specialised recovery options may need to be connected to regional, national or supranational recovery networks. There is no one-size fits all solution as recovery facilities depend on scale, technology, subsidies and possible re-users of the recovered materials. A fundamental questions are: who pays for the waste and how is costly material recovery subsidised?

[Solution] Provide material recovery facilities based on the scale that they function most efficiently for both the waste producer and the use/treatment of the specific waste stream. Before defining what kind of material recovery facilities could be implemented, the composition of urban waste must be better understood, which can be done with a R.12 Material Database. The design criteria for accessibility and a hierarchy of facilities can be then considered strategically at different geographical scales. As waste can lead to congestion, waste transport should be considered at a metropolitan scale for R.8 Moving Things Efficiently. To minimise congestion and potential hazards, N.5 Local Collection Points of Segregated Waste may reduce accessibility problems to recovery facilities by consolidating waste and reducing unnecessary transport. Having the segregated waste collection points connected to recovery facilities through the R.12 Material Database, the most common waste streams can be dealt with according to demand. Social enterprises (R.4 Availability of Diverse Jobs), with public subsidies, can be supported to deal with manual labour based around treating low value materials while private companies can be engaged to treat high value materials. Locating facilities adjoining C.7 Links to Transport Infrastructure can provide opportunities to use lower emissions and efficient combinations of transport modes while adapting to the R.7 Multi-Scalar Circular Infrastructure and recovery options beyond the city.

[Contribution] Add contributions here.