R.6 Sustainable Product Cycles

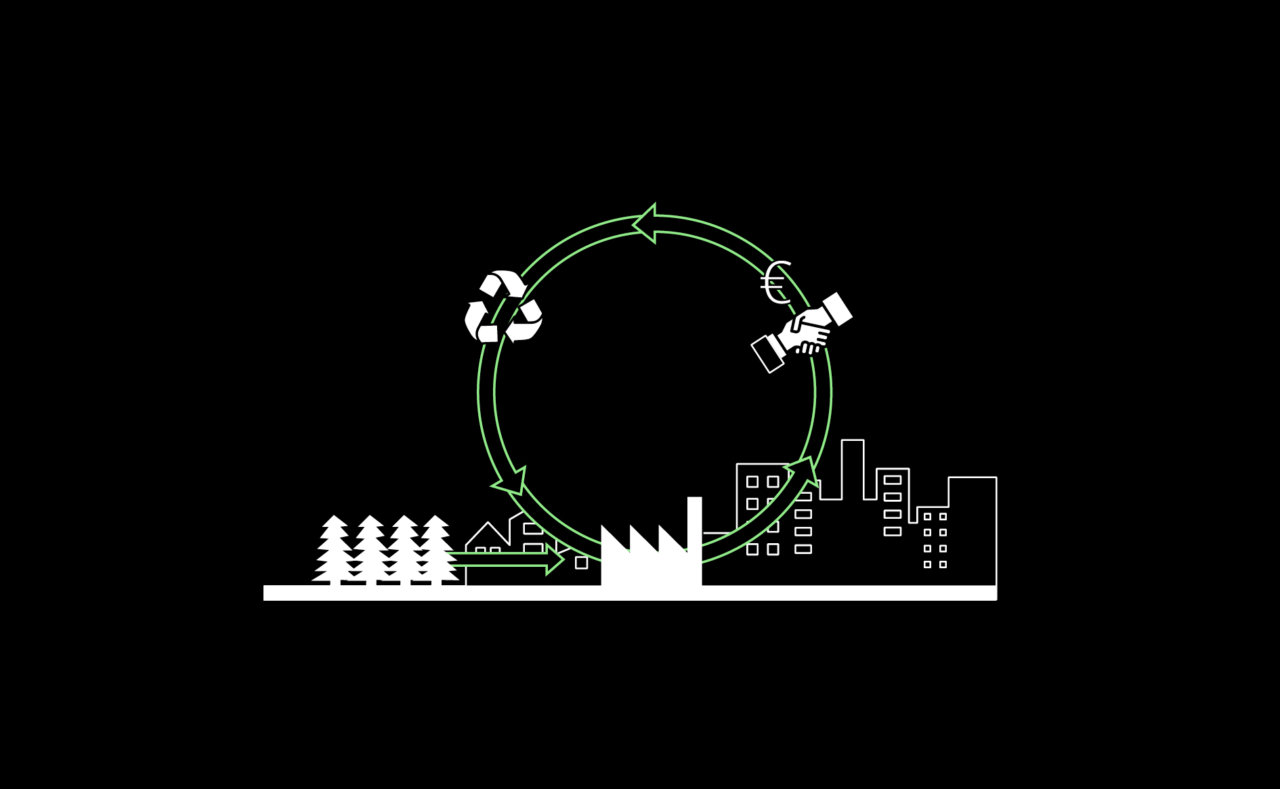

Manufacturing contributes to city-scale circularity, helping reduce distances from resource to processing site, distribution and retail, and then to re-use, remanufacture, material recovery and back to the production cycle.

[Context] The product cycle is the period between production, consumption and waste of a product. Over the last century product cycles have become increasingly shorter. This results in serious environmental impacts with large amounts of resources being used and disposed of within a short period of time. Some of these resources are highly critical and hazardous if released in the environment. This has been paired with increasingly complex supply chains that detach places of production from places of consumption while forcing down prices of goods such as electronics, furniture or textiles. Furthermore, shorter product cycles have led to large volumes of waste and unused stocks accumulating in cities with poor opportunities to be used productively. Slowing down product cycles, to reduce environmental impacts, requires increasing the durability of products and the opportunities derived from extending the use of products through repairing, maintenance and remanufacturing processes. The city scale, where distances are shortest to the final consumer, are ideal locations to provide a space for new business models to emerge and through urban manufacturing to design better adapted products, extend their durability and recover useful components and materials at the end of their use life.

[Problem] The high cost of space close to clients and the low cost of technology makes it challenging for businesses operating with sustainable product cycles to remain viable. There is also little incentive for consumers to keep technology and goods functional as long as possible due to the low cost of consumer and professional goods and the fact that consumers do not pay for the waste costs upfront. This renders products increasingly dispensable and conversely increasingly difficult and expensive to repair. Few public authorities see it as their responsibility to invest in repair or re-use, yet pay the price through waste management. Furthermore, due to the complexity of waste management, there are only a small number of large resource management companies that can afford to invest in transitions to sustainable product cycles. Finally, skills in repair are not being stimulated, making technical capacity increasingly limited. The net result is a limited capacity for cities to repair or maintain products, with little opportunity for remanufacturing and recovery of materials at the end of the product life cycle.

[Forces] Currently private R.7 Multi-scalar Circular Infrastructure favours extracting only the profitable resources while disposing low-value components. Regardless, there are two opposing forces affecting consumption patterns. Firstly, there is a large supply of cheap and short lived products that have not been designed to be repurposed or recycled, generally from off-shore manufacturing. By contrast, regulation and growing consumer preferences is forcing companies to adopt different business models where there is increased attention to materials contained in products and responsible treatment of materials at the end of life of products. The best approach available for both consumers and public authorities is to use more resilient and longer-lasting products, yet this often comes with a cost.

[Solutions] Ensure suitable facilities are available to repair or re-use broken goods. Where possible, public and private investment should prioritise high quality goods to minimise the likelihood of failure. Purchasing equipment and goods that can be easily repaired. For sustainable product cycles to be enacted, urban planning and economic policies must recognise the network of infrastructure to provide a regenerative service for goods and materials consumed within cities. This can be done through addressing and mapping out the spatial needs associated with repair, storage, recycling and waste. Each will have different resource management systems at the city or regional scale. Provide a variety of spaces and R.7 Multi-scalar Circular Infrastructure to address both collection points and levels of waste treatment. Recycling should be considered as the last viable option (after repair or remanufacturing). N.5 Local Collection Points of Segregated Waste are importantly linked to B.8 Space for Storage to allow material stockpiling. This can give entrepreneurs or N.7 Local Design and Prototyping organisations an incentive to turn waste into resource. Where possible build on existing waste management processes to ensure that users understand where waste must go and where to repair fixable things. However, where the system is blocked by regulation or policy, explore how to adapt it. In some cases, such as for organic materials, legislation may need to be changed to make the resource circular. Businesses that have their waste collected, should sort waste as best possible at the source so that the waste can be taken to a suitable treatment site – penalise those that fail to do so through R.10 Place-based Financial Levers. P.6 Re-use & Repair Centres, both privately managed and public centres, can be located near consumers or businesses to help lengthen product cycles while offering accessible and meaningful low-skilled work.

[Contribution] Add contributions here.