N.2 Re-use of Material & Energy Flows

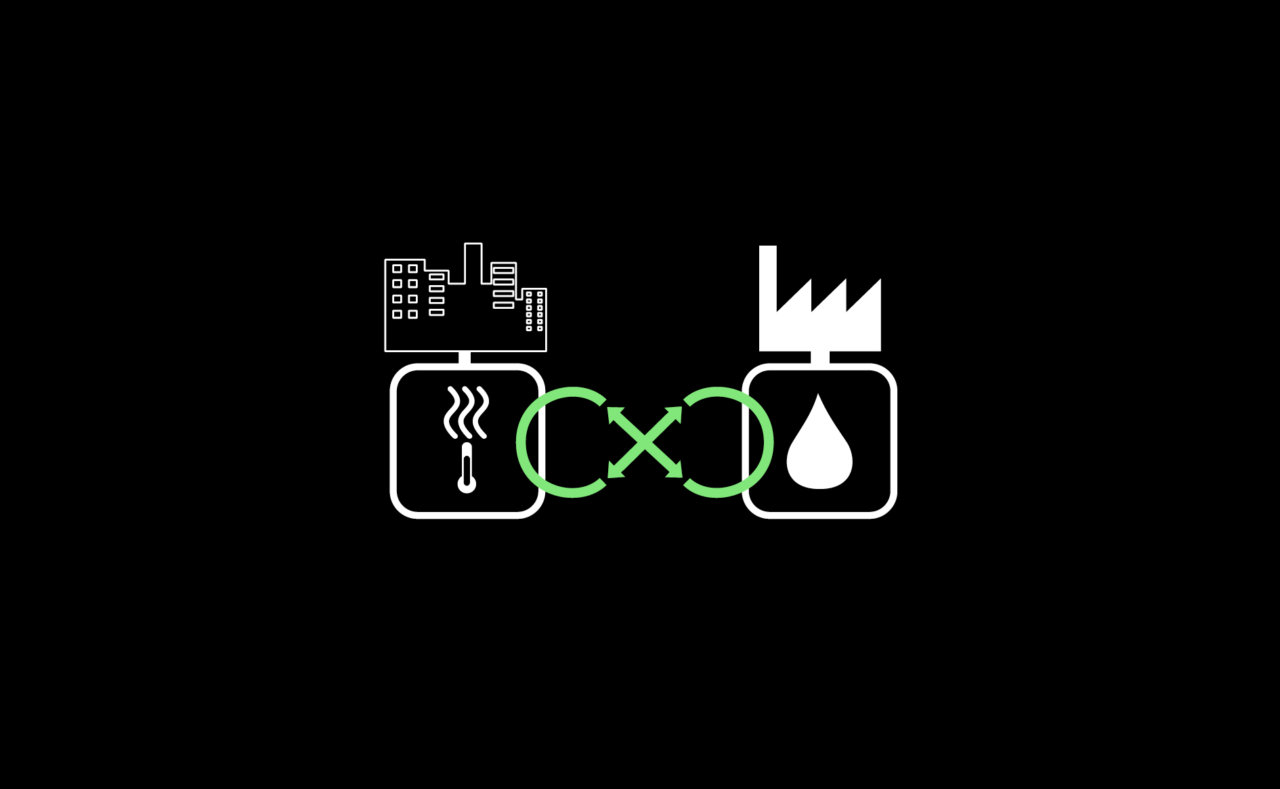

Local production of waste water, materials and heat could be turned into innovative new uses, to reduce the dependency on primary raw materials and reduce environmental pressures.

[Context] Large volumes of waste generated by cities can be considered a local resource that with adequate planning and infrastructure can be put to productive local use, helping to close loops for resource demands. Manufacturers have much to gain from this as they have large demands for materials and are a source of considerable waste. Cities require policies for treating waste locally and means to capture the waste for local use, to avoid it being exported. Manufacturers are also needed that can convert waste into a usable resource, while others are required for converting such resources into products.

[Problem] Although cities produce large volumes of waste materials, water and heat, most of it is dispersed or disposed of, increasing the urban environmental impact of waste. This is in part due to issues surrounding governance of resources and waste. The legal and institutional framework around waste can mean that usable resources or potentially valuable waste streams are not recovered due to the administrative restrictions imposed on the movement and exchange of waste. This becomes increasingly complex in cities where waste responsibilities are divided among different departments, agencies or even political interest groups, creating a complex architecture of decisions surrounding waste movements. Quick wins for waste management involve mining valuable materials such as steel, copper, gold and so on where there is a well established secondary market. However, on the whole much of the material waste produced in urban areas is of little value compared to the cost of processing it, especially with respect to household waste and mixed waste streams. Furthermore, concepts behind ‘energy cascading’, in other words using residual heat from one user to provide heat for another user, requires expensive upfront infrastructure costs for piping. Likewise, water is also an undervalued resource that is by default sent into the sewage network as other options tend to be more expensive if they are not considered early in the design and planning process. As a result, re-use of material and energy flows requires extensive support.

[Forces] There are plenty of sensible ideas for improving the management of material and energy flows conceived particularly by designers and engineers. However complexity of the resource management system is often far too overwhelming for individual businesses to improve their own material or energy flows even if there is genuine interest. Even manufacturers interested using waste streams can be plagued by red tape. Business models often require a large one-off infrastructure investment (such as a pipe network for heat exchange), which can involve using public space and expose a certain institutional complexity in terms of permits and financing. Businesses can also get worried about path dependency through building heavy inter-dependence with a vulnerable resource (such as heat). Furthermore, questions of intellectual property can be highly limiting in terms of what kinds of knowledge and material sharing could occur between businesses and public authorities, and how to avoid possible industrial knowledge theft. Finally, there is rarely the political mandate or financial instruments (such as incentives, loans or taxes) to stimulate or force businesses to collaborate (C.10 Place-based Financial Levers). Among all these obstacles, the main hindrance is a current lack of understanding and visibility of material and energy flows between activities at the city level (R.10 Material Database), which reduces the chances to identify potential for reutilisation.

[Solutions] Take advantage of waste materials and unused energy, by developing workable synergies between waste creators and business that can re-use the waste. Resource recovery requires addressing three aspects. Firstly it requires an understanding of the flows of material, water and energy within the system which can be done with a R.12 Material Database. Secondly it requires appropriate R.7 Multi-scalar Circular Infrastructure to be able to recover the resources. This could involve N.5 Local Collection Points of Segregated Waste or C.8 Accessible Material Recovery Facilities which could be combined within a N.6 Centralised Logistics Zone. New projects should take resource recovery into consideration by ensuring sufficient B.8 Space for Storage, particularly for B.1 Making Around Courtyards where waste can be easily sorted or where businesses could exchange their waste. Thirdly, system interventions are required to engage city stakeholders and to create incentives to encourage stakeholders to re-use local material and energy flows. R.10 Place-based Financial Levers could also be activated. A R.3 Curator or area manager could help provide a matchmaking service between supply and demand of materials particularly where there is a strategy for N.3 Mixing Complementary Making and Related Services by curating systemic relationships between individual actors. Where no clear business model is available to manage waste, R.11 Incentives for Research & Development could be considered to build local innovation.

[Contribution] Add contributions here.